crown Silo Bags

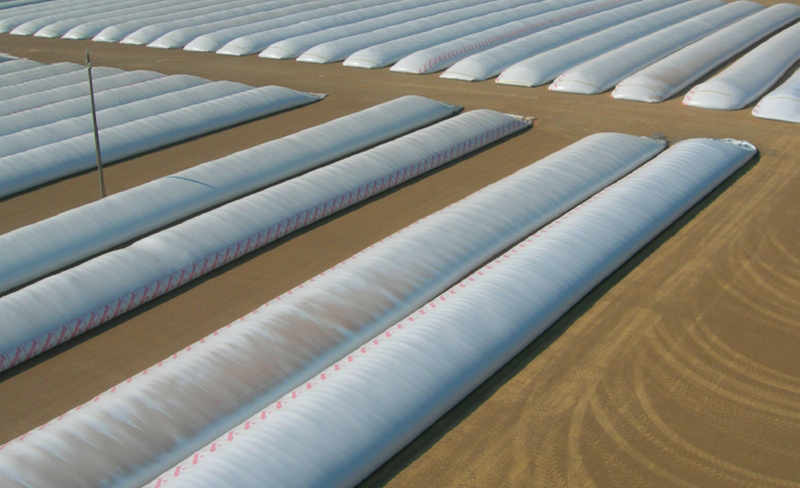

Crown Silo Bags are made of a seven-layers of Blown extruded technology with various polymers to achieve the best quality Silo Bags (Polyethylene) about 180-250 micron.

Images used are for representative purpose only.

The diameter of 8-10 feet and Length of 60 m, 75 m up to 90 m can be produced. Every Bag is folded with an automatic folding machine.

The outer layer is white with UV protective coating while the inner layer in contact with the grain is black.

Applications of crown silo Bags

Ideal for storing all kinds of grains, dried fruits, fertilizers, fodder, and other stuff.

Sealed immediately after filling up, trapping the oxygen that’s used up by the grains and produces carbon dioxide. The anaerobic condition prevents the formation of fungus or insects in the bags

Special machines are used to load and unload grains and other products from these bags.

Advantages of crown silo Bags

Retains original quality and quantity of the products

Ideal for long term storage

Perfect sealing and anaerobic conditions expel insects and fungus growth within the bag.

Protects the goods from adverse climatic conditions during transit.

Lower investment costs and lower total annual costs.

Silo Bag Specifications

| Sl.No. | Specifaication | Units | Standard |

|---|---|---|---|

| 1 | Width | mm | In house |

| 2 | Thicknes | micron | In house |

| GSM | 180 - 240 | ||

| 3 | Tensile Strength - MD | kg / cm 2 | ASTM D882 |

| 4 | Tensile Strength - TD | kg / cm 2 | ASTM D882 |

| 5 | Elongation MD | % | ASTM D882 |

| 6 | Elongation TD | % | ASTM D882 |

| 7 | Dart Impact Method - B | grams | ASTM D1709 |

| 8 | COF - Static | ASTM D1894 | |

| 9 | COF - Static | ASTM D1894 | |

| 10 | WVTR | gm / ms 2 / day | ASTM F1249 |

Three or five or seven co-extruded layers of polyethylene plastic film UV protected.

Sizes:

a. Diameter of 7 to 12 feet

b. Length of 60m, 75 m, 120 m or higher (inhouse automatic folding machine)

Capacity ranges from 180-250 tons or higher (for dry products)

a. Dry products: soft wheat, durum wheat, maize, sorghum, soybean, rice, barley, sunflower, oats, every grain product.

b. Wet products: grains of any kind, silage, biomasses, mush, by products of industrial processes, forage.

Crown Silo Bag Sizes

| Size | Thickness | Bags / Pallet |

|---|---|---|

| 9' x 200' | 9.3 mil | 8 |

| 9' x 250' | 9.3 mil | 6 |

| 10' x 250' | 9.3 mil | 6 |

| 10' x 300' | 9.3 mil | 6 |

| 10' x 500' | 9.3 mil | 2 |

| 10.5' x 500' | 9.3 mil | 2 |

| 12' x 200' | 10 mil | 4 |

| 12' x 300' | 10 mil | 4 |

| 12' x 400' | 10 mil | 2 |

| 12' x 500' | 10 mil | 2 |

Silo Bag Mounting Instructions

step 1

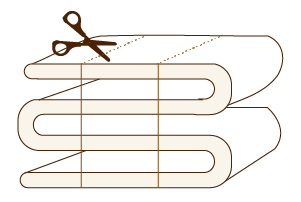

Take out the SILO bag from the box.

step 2

Cut the blue cords taking care NOT TO CUT the white cords.

step 3

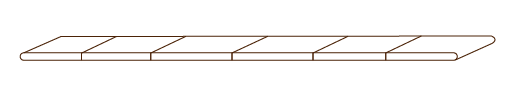

Open, unfold and lay it out flat as shown below

step 4

Place the bag right between the backstop and the tunnel, with the black folded edges facing the tunnel and the white edges facing the backstop.

step 5

Now mount the bag onto the machine pushing it far forward.

step 6

ORotate the bag, so the plastic is levelled on the holding pan under the tunnel with the logo facing the side of the tunnel.

step 7

Now remove all the remaining white cords.

step 8

Grab the plastic at the lower inside edge and pull out almost 8-10 feet of the bag. In the case of grains, the bag has to be pulled from the outside edge.

step 9

Now attach the stretch rope and seal the free end.

step 10

Ensure that the bag is not binding on the machine, the rope and pan are well fastened.

step 11

Also ensure the ‘stretch bars’ with the filled bag DO NOT exceed 11” in height.

step 12

Extra room will be needed for expansion.

step 13

The RED rape you see near the logo indicates that 5 folds remain until the end of the bag.

step 14

On completion of filling seal, the open end immediately.

step 15

Now vent the bag quickly with a 3” to 4” strip of repair tape on the finished end.

step 16

Make a 1-inch ‘X’ through the tape and bag and let it vent for 2 to 3 days till it stops releasing the gas built up within and reseal. Please note that inhaling silage gases is hazardous.

Silo Bag Capacity chart

| HEY SILAGE | CORN SILAGE | EAR CORN | GROUND SHELLED CORN | SHELLED CORN | GRAIN | |

|---|---|---|---|---|---|---|

| Bag Size | Tons | Tons | Bushels | Bushels | Bushels | Bushels |

| 8 x 150 | 120 -140 | 140 -150 | 3200 | 4500 | 4500 | 4600 |

| 8 x 200 | 170 -180 | 190 -200 | 4300 | 6200 | 6200 | 6350 |

| 9 x 150 | 150 -170 | 160 -190 | 3900 | 5500 | 5500 | 5650 |

| 9 x 200 | 190 -210 | 220 -240 | 5300 | 7500 | 7500 | 7680 |

| 9 x 250 | 260 -280 | 280 -300 | 6600 | 9500 | 9500 | 9730 |

| 9 x 300 | 315 -335 | 340 -360 | 8000 | 11500 | 11500 | 11780 |

| 10 x 200 | 280 | 300 | 6100 | 8700 | 8700 | 8900 |

| 10 x 250 | 355 | 380 | 7700 | 11000 | 11000 | 11275 |

| 10 x 300 | 430 | 460 | 9400 | 13400 | 13400 | 13730 |

| 10 x 400 | 580 | 620 | 12700 | 18100 | 18100 | 18550 |

| 10 x 500 | 730 | 780 | 16000 | 22800 | 22800 | 23370 |

| 11 x 300 | 480 | 510 | NA | NA | NA | NA |

| 12 x 300 | 570 | 630 | 11500 - 13950 | 16530 - 19950 | 16530 - 19950 | 16530 - 19950 |

| 12 x 500 | 970 | 1070 | 19650 - 23800 | 28100 - 33950 | 28100 - 33950 | 28100 - 33950 |

| 14 x 500 | 1300 | 1360 | NA | NA | NA | NA |